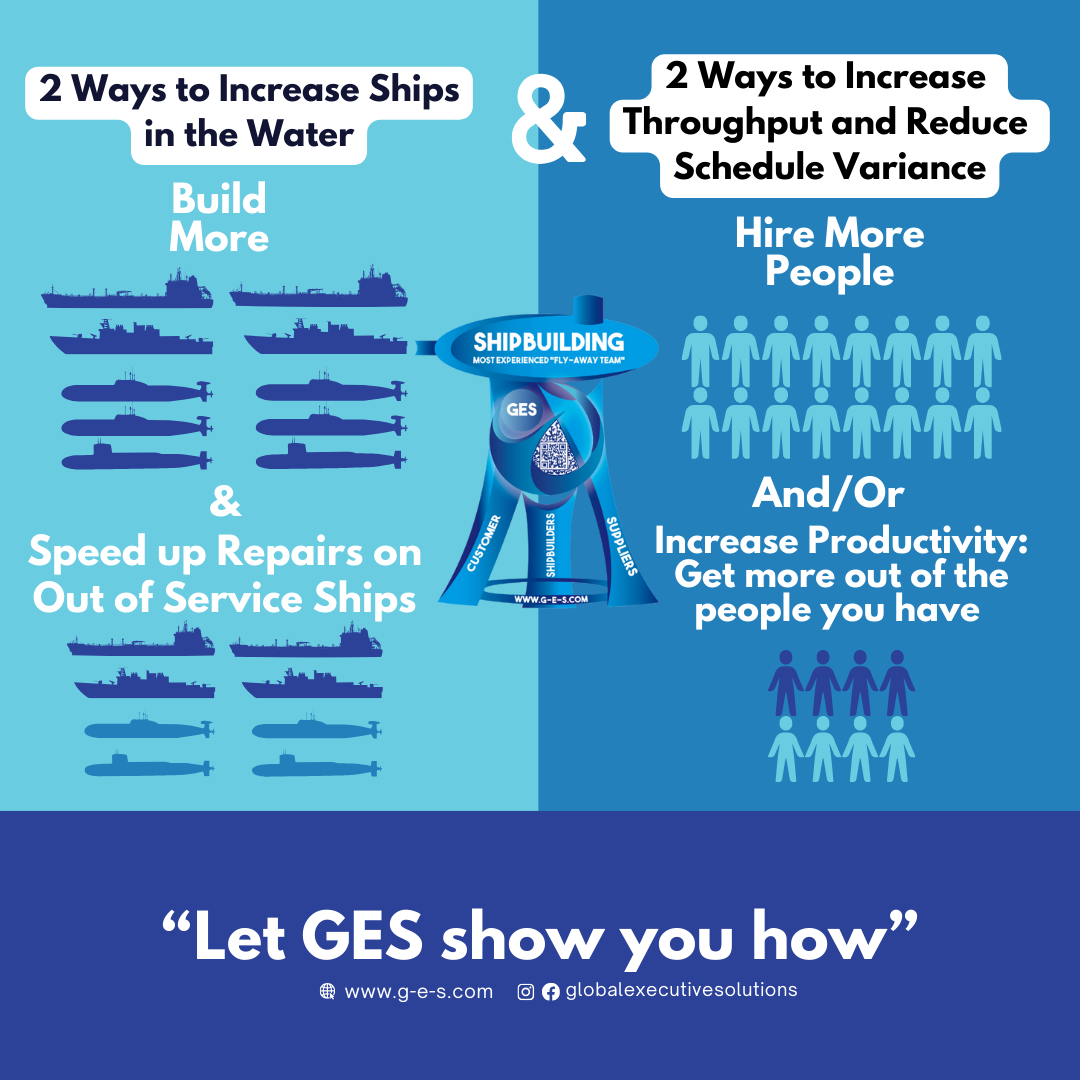

In recent years, many companies have found themselves falling farther behind schedule and under intense pressure from their customers to meet delivery dates. This can’t be more true for DoD Manufacturers and their suppliers who are hit with National Security concerns on the line. There are two viable paths to success: Hire more people or figure out how to get more out of what you have.

The common response might be to hire more people to close the gap in schedule attainment. While traditionally believed to be the most effective option, this is not always the best choice to make. This may be shocking to many industries that are constantly under pressure to meet customer deadlines. Many of these same industries follow a modeling system that stands by the notion: “to produce X amount of product, you need to have Y amount of people working.” But what about the hidden factors that are overlooked? Does this practice consider basic assumptions like CPI (Cost Performance Index) which is used to measure success? In simple terms, how many hours of productive/billable work (aka Earned Hours) are you getting out of an 8-hour shift?

- CPI: “Cost Performance Index.” For example, CPI of 0.6 means your Earned Hours is only 60% of your paid hours. For more info refer to (How to Minimize the Negative Impact of Hiring on Cost Performance).

- Green Labor Impact on CPI: Several studies have been done on the hidden cost of hiring. What has been proven on numerous occasions is that when adding new employees, you not only get a mere 50% productivity at best in the first 6-9 months, but you

also decrease the hours earned from your senior/experienced people. Why? They are the ones who will stop their own tasks to assist the green labor. Not to mention that Green labor is the most frequently used explanation/excuse for increased cost and delayed schedule.

Schedule and cost attainment is critical to many industries, especially in the national defense sector of manufacturing. However, conducting a National Recruiting Campaign and overwhelming the sector with a massive influx of “Green Labor” may not be the best or only option. It is certainly not the only choice.

The best option may be to explore ways of “Getting more out of the workforce you have.” In doing so, you will be maintaining a healthy absorption rate.

In closing, by focusing on enhancing productivity and minimizing disruptions caused by inexperienced hires, organizations can maintain cost-effectiveness and achieve more predictable outcomes. It is important to support operational goals and foster a sustainable and resilient workforce capable of exceeding expectations in challenging environments. There are many proven tools to help the industry increase throughput. This includes but is not limited to: Work Order Management, Leader Standard of Work, and Management Operating Systems just to name a few. The GES Team has successfully implemented many of these specific programs over the last 30 years, leading DoD manufacturing facilities to better practices and solid improved results. Let us help your organization exceed expectations.